You might have heard your dentist mention a CEREC® crown, but perhaps you are unclear about what a CEREC crown is. When you have a damaged tooth, the dentist will suggest several options for repairing the tooth, based on the type of damage and your oral health. Worn-down or teeth damaged by tooth decay are candidates for repair with crowns. Not all types of crowns are the same. CEREC crowns offer you a durable crown that looks natural and will last a long time. Here is how your dentist will use CEREC technology to design your crown.

You might have heard your dentist mention a CEREC® crown, but perhaps you are unclear about what a CEREC crown is. When you have a damaged tooth, the dentist will suggest several options for repairing the tooth, based on the type of damage and your oral health. Worn-down or teeth damaged by tooth decay are candidates for repair with crowns. Not all types of crowns are the same. CEREC crowns offer you a durable crown that looks natural and will last a long time. Here is how your dentist will use CEREC technology to design your crown.

Why choose CEREC

When a patient has a damaged tooth, the dentist will offer several options to repair the damage and preserve the tooth. CEREC stands for Chairside Economical Restoration of Esthetic Ceramic. It is an increasingly popular way to create a custom-fit crown at the dentist’s office. There are many options for crowns besides CEREC, but more and more people are opting for CEREC over more conventional choices.

An individual fit

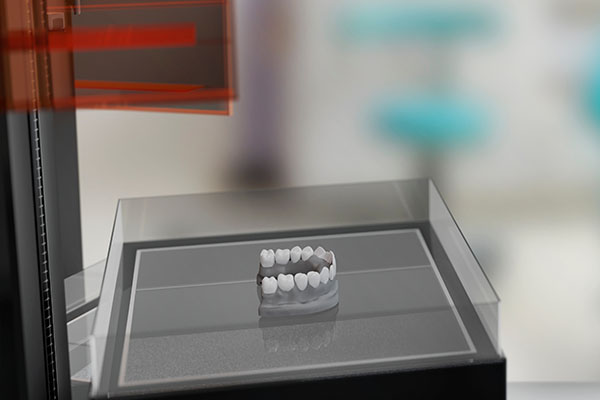

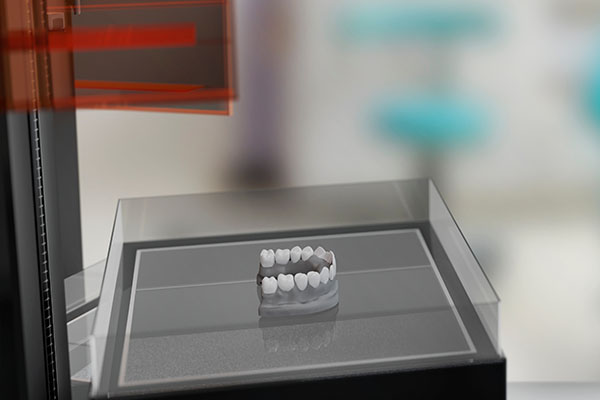

Dentists use computer-aided design (CAD) and computer-aided manufacture (CAM) to create a CEREC crown. Using accurate measurements, the dentist uses a program to craft a crown to fit the patient’s damaged tooth. The dentist can use impressions to match the patient’s natural bite when creating the new crown. In some cases, the dentist can also scan the patient’s mouth.

Accurate equipment in-office

The program that designs the custom crown sends the information to the machine. The machine receives the measurements from the software and mills the crown down to closely mimic the patient’s tooth. The resulting crown is accurate. The dentist will install it and have the patient test it by biting. The dentist can make further refinements to the crown to ensure a good fit.

A faster process for greater success

Dentists create CEREC crowns in the office. For most patients, the entire process is very efficient and takes only one visit. With other types of crowns, dentists often have to take impressions and send the impressions to an outside lab. There is a greater risk for error, and patients must also make several appointments until the dentist has completed the work. The milling process for a CEREC crown can take as little as 15 minutes.

Preparing the tooth

The dentist will shape the tooth that needs the crown while the machine crafts the crown. Trimming the tooth allows the CEREC crown to fit closely on the existing tooth. If the crown is covering a cavity or tooth decay, the dentist may open the cavity slightly. Before the dentist installs the crown, they will remove any tooth decay infection.

CEREC provides a better fit and greater comfort

Advances in dental technology mean you do not have to make do with poorly fitting crowns anymore. CEREC crowns fit so well, you may forget you had the procedure. You can get a natural-looking crown in only a single dentist visit with CEREC. Your dentist can help you decide if this is a good option for you.

Request an appointment or call Woodland Park Dental at 801-416-1603 for an appointment in our Layton office.

Related Posts

A CEREC dentist uses advanced dental technology to give patients high-quality restorations in a single appointment. This technology is revolutionizing the way crowns, veneers, and other dental restorations are made. If you value efficiency, precision, and convenience, working with a CEREC dentist can transform your dental care experience.CEREC, which stands for Chairside Economical Restoration of…

CEREC® can fix your damaged tooth. You should see your dentist right away if you have dental damage. Before the procedure begins, your tooth must go through some preparations. The dentist must make sure that your tooth is ready for the ceramic crown. Here are the details on how your dentist will prepare your damaged…

CEREC® (Chairside Economical Restoration of Esthetic Ceramic) ceramic crowns are innovative restorations. Patients appreciate the many advantages of CEREC crowns over traditional crown materials. The technology of these restorations continues to bring bigger smiles in many communities. Choosing CEREC ceramic crowns is an easy decision. If you want to know why, here are the details.CEREC…